Core Drills or Hole Saws: What is the difference?

Core Drill Bits (also known as Annular Cutters or Broach Cutters) share a lot of similarities with Hole Saws, as they only cut the outer edge of a hole. They cut a groove around the outside of the hole, leaving a solid core or slug in the middle of it. However, there are differences when it comes to Core Drills vs Hole Saws.

What are Core Drill Bits used for?

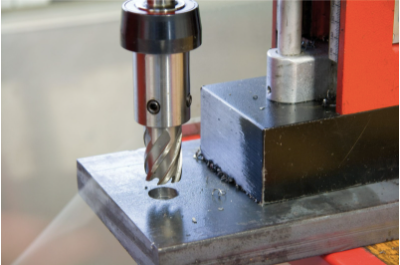

Diamond Core Drills (commonly referred to as Annular Cutters and occasionally Broach Cutters) are predominantly used with Mag Drill Machines. They can also be used with other drilling machines such as mills or huge drill presses with tool holders. Core Drill Bits are a single piece tool with a much smaller diameter in comparison to Hole Saw Cutters. They consist of a shank (for attaching to the drill machine/device), a pilot, flats, flutes and a cutting edge. The hollow cocooned flute allows for chips acquired by the drill bit to be ejected during the drilling process.

Diamond Core Drills (commonly referred to as Annular Cutters and occasionally Broach Cutters) are predominantly used with Mag Drill Machines. They can also be used with other drilling machines such as mills or huge drill presses with tool holders. Core Drill Bits are a single piece tool with a much smaller diameter in comparison to Hole Saw Cutters. They consist of a shank (for attaching to the drill machine/device), a pilot, flats, flutes and a cutting edge. The hollow cocooned flute allows for chips acquired by the drill bit to be ejected during the drilling process.

Core Drills are ideal for metalwork projects. Due to their shape, structure and robustness, Core Drill Bits can handle more heavy-duty industrial and construction processes. Most drill bits are capable of the following metals:

|

Steel (typically up to 900 N/mm2 Thick) |

✔ |

|

Aluminium |

✔ |

|

Brass |

✔ |

|

Bronze |

✔ |

|

Cast Iron |

✔ |

Alongside these metals, Core Drills or Annular Cutters can handle most types of plastics.

You can learn more about Core Drill Bits with our article on “How to use a Core Drill”.

What are Hole Saw Cutters used for?

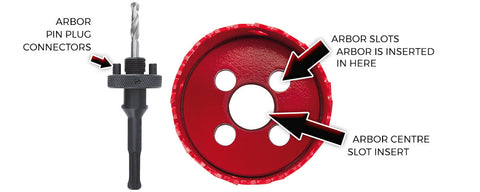

Hole Saw Cutter Tools allow for a much wider diameter of hole to be created within a surface material. Typically, Hole Saws require an Arbor Pilot Drill with the holder attachment accessory to accompany it on a drilling task to help create a hole.

Hole Saws can be used on either portable handheld drill devices or industrial standing drilling machines. They provide a great solution for wider hole creations such as cable organisers within desks, installing QI wireless charging pads/docks and building/DIY constructions such as drilling through plasterboards, fibreboards, plywood and other light building boards. In comparison to Core Drill Bits, Bi-Metal Hole Saws can usually handle lighter materials such as wood and light non-ferrous metals, whereas Tungsten Carbide Hole Saws can handle stronger metals such as Stainless Steel, Thicker Stronger Steel and Titanium Alloyed Metals. Most Hole Saws are capable of the following Surface Materials:

|

|

Bi-Metals Hole Saws |

Tungsten Carbide Hole Saws |

|

Steel (typically up to 900 N/mm2 Thick) |

✔ |

✔ |

|

Steel (typically up to 1100 N/mm2 Thick) |

|

✔ |

|

Steel (typically up to 1100 N/mm2 Thick) |

|

✔ |

|

Stainless Steel |

✔ |

✔ |

|

Aluminium |

✔ |

✔ |

|

Brass |

✔ |

✔ |

|

Bronze |

✔ |

✔ |

|

Cast Iron |

|

✔ |

|

Titanium Alloyed |

|

✔ |

|

Plastics |

✔ |

✔ |

|

Wood |

✔ |

✔ |

You can find out more about Hole Saw Cutters in our “Hole Saw Guide”.

|

Bi-Metal Hole Saw Cutters |

Tungsten Carbide Hole Saw Cutters |

|

|

|

Other Alternative Tools

Screw Hole Punches

Screw Hole Punches

A Screw Hole Punch Tool consists of 4 Parts to it. These include the Punch, the Traction Bolt, the Die and the Ball-bearing. It is suited for more lighter, thinner pieces of metal to prevent restructuring and reshaping (bending) or potential breakage of the surface metal that could be caused by Hole Saws or Core Drill Bits. One example of applicational use, is hole cutting within Kitchen Sinks. They are not ideal for thicker materials and wider diameter hole cutting where Core Drills or Hole Saw Cutters would be more suitable.

Step Drill Bits & Sheet Drill Bits

Step Drill Bits & Sheet Drill Bits

Due to the cone shaped structure of Step Drills, these are designed to enlarge an already existing hole. The end tip of the drill bit provides a precise point of contact with the surface material when drilling. From there, each “step” or groove in the drill bit is slightly larger in diameter compared to the last. A disadvantage to these drill bits over Hole Saws and Core Drills is the restricted maximum diameter of drilling where the other two can have the potential to expand to.

Tube and Sheet Drill Bits are similarly conical shaped like Step Drills and are used for sheet metal drilling. However, unlike Step Drills, Sheet Drills are smoothed surface with no step diameter increases. The diameter increase instead is with a one-step flow (smooth) increase. As with Step Drill Bits, Tube and Sheet Drills are limited to a maximum Hole Size Diameter compared to Core Drills and especially Hole Saws.

Standard Jobber Twist Drill Bits

Standard Jobber Twist Drill Bits

Most Common drilling is executed by a variation of a Jobber Twist Drill Bit. These are ideal for minuscule small holes or screw related workpieces. Whilst these are the most notorious drill bits, used for most standard DIY jobs, they are not best suited for larger hole drilling where a larger diameter is required within a work surface.

In conclusion, ensuring you have the correct hole cutting tool to hand is strongly dependant on the material surface, hole diameter size and drilling process that will need to take place. Core Drills are more suited to more robust and slightly smaller diameter hole drilling, whilst Hole Saws can provide a much wider bigger diameter hole but within lighter materials like light metal, wood materials and plastics. Quality Tools UK supply a large range of Hole Cutting Tools such as Core Drill Bits/Annular Cutters, Hole Saws (alongside ARBOR Holders and Pilot Drill Bits), alongside Step Drill Bits.

|

Deburring Tools Once a hole is drilled, be sure to fine tune it by removing any burrs and ensuring a burr-free hole with our extensive selection of RUKO Rotary Burr Products or RUKO DeBurring Blades from Quality Tools UK with Free Delivery on Orders over £50! |

|

- 0 comments

- Tags: Aluminium Drilling, Annular Cutters, Brass Drilling, Broach Cutters, Bronze Drilling, Cast Iron Drilling, Construction Tools, Core Drills, DIY, Drills, Hole Cutters, Hole Saw, Plastic Drilling, RUKO, Screw Hole Punch, Steel Drilling, Step by Step Guide/Demonstration, Step Drills, TERRAX, Titanium Drilling, Wood Drilling, Workshop Applications

0 comments